LOMBARDI

Here, at A&A Labels, the Lombardi-Synchroline flexographic press plays a key role in delivering precise, high-quality label and packaging solutions. Powered by advanced servo-driven technology and intelligent automation, Synchroline ensures consistent results with minimal operator input.

Its versatility allows us to print on a wide range of materials, including BOPP, PET, PVC, PE, adhesive paper, thermal paper, and cardboard—making it ideal for diverse applications. With a fully modular design, Synchroline supports advanced features like multi-layer printing, hot and cold foiling, and screen printing, giving us the flexibility to meet both simple and complex production needs.

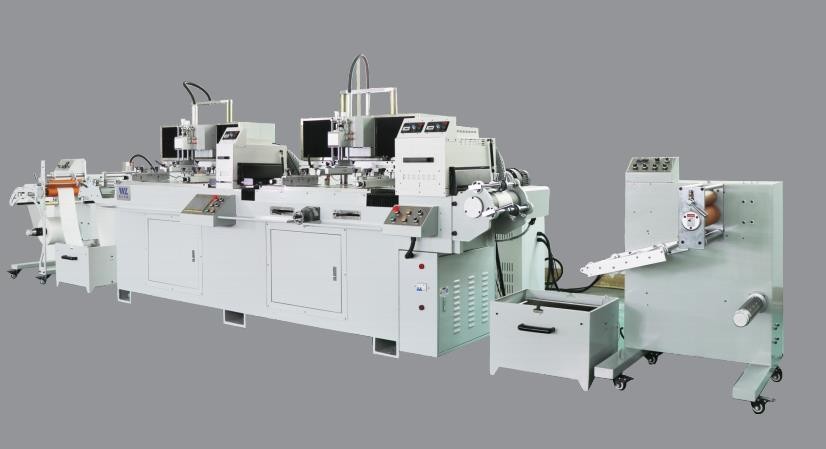

MULTITECH

The Multitech press features fully servo-driven print units, each equipped with pre-register and auto-register systems for precise control along the web direction. Its servo infeed, open-access design, quick-change print cylinders, and short web path UV configuration work together to deliver exceptional print quality while significantly reducing material waste.

KOMORI OFFSET

At A&A Labels, we utilize the Komori Offset Press—an industry favourite for premium packaging production. Known for its outstanding accuracy, speed, and adaptability, this advanced press enables us to produce folding cartons, labels, and a variety of other packaging materials with vivid colour and sharp detail. Its quick setup times and high-speed capabilities make it ideal for both short and long print runs. With support for a wide range of substrates, the Komori press gives us the flexibility to meet diverse packaging requirements, ensuring consistent, high-quality results every time.

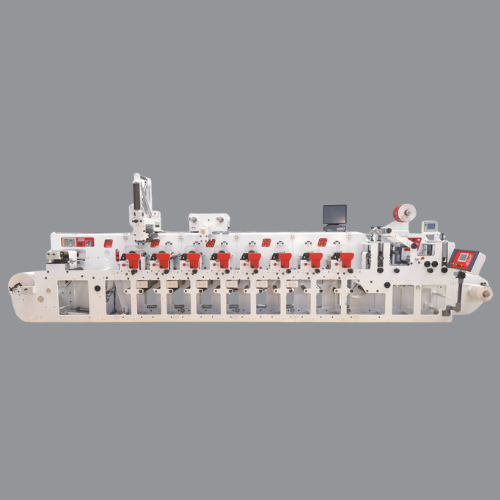

Screen printing

We’ve installed state-of-the-art screen printing machines, specially designed for high-end embellishments. From striking UV effects to high-gloss and embossed finishes, we now offer premium upgrades that add depth, texture, and brilliance to your labels and stickers—perfect for brands looking to stand out.